Top Benefits of Hiring Experts for Welding Inspection Madison

Top Benefits of Hiring Experts for Welding Inspection Madison

Blog Article

Exactly How Reliable Welding Inspection Enhances Structural Honesty and Long Life

In the world of building and design, the relevance of welding inspection can not be overstated, as it plays a critical function in making sure architectural stability and prolonging the life expectancy of jobs. By releasing a variety of advanced inspection strategies, such as radiographic and ultrasonic testing, experts can pinpoint flaws that might endanger the integrity of a framework. The question continues to be: just how do these careful processes convert right into tangible advantages for longevity and safety and security? Sign up with the expedition of how effective welding evaluations can transform prospective vulnerabilities right into strengths, contributing to the long-lasting success of buildings.

Relevance of Welding Examination

Guaranteeing the architectural honesty and security of welded buildings mandates rigorous welding assessment procedures. Welding examination works as a vital guard in the construction and production industries, where the stamina and resilience of joints dramatically impact the general efficiency of frameworks. This examination guarantees that welds satisfy details standards and specs, decreasing the risks connected with architectural failures. The repercussions of poor welds can be devastating, leading to expensive repairs, operational downtimes, or also disastrous failures, every one of which highlight the paramount importance of complete examination.

In addition to safety and security, welding assessment plays a vital role in top quality assurance. By sticking to fixed requirements, assessments determine the consistency of welds, making certain that each satisfies the desired strength and visual demands. This consistency is vital not only for safety yet likewise for maintaining the reputation and integrity of producers and fabricators. Additionally, regulatory conformity is a significant driver of welding inspection methods. Industry requirements and codes, such as those from the American Welding Culture (AWS) or the International Company for Standardization (ISO), require adherence to strict standards, underscoring the relevance of evaluations in satisfying these lawful and expert responsibilities.

Key Inspection Techniques

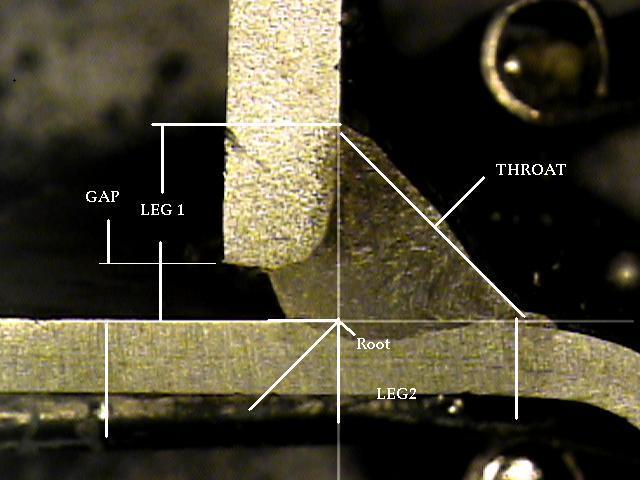

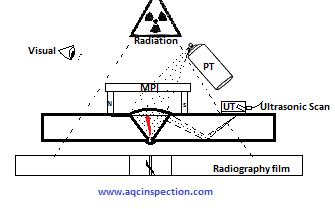

Ultrasonic Checking (UT) utilizes high-frequency acoustic waves to spot subsurface imperfections, offering precise information regarding weld stability without creating any kind of damages. Radiographic Testing (RT), involving X-rays or gamma rays, offers a comprehensive picture of the weld's inner structure, revealing covert flaws. Magnetic Bit Examining (MPT) is another non-destructive method, especially efficient for discovering surface area and near-surface suspensions in ferromagnetic products.

Penetrant Screening (PT) involves the application of a liquid color to disclose surface-breaking defects, using a uncomplicated and cost-effective option for non-porous products. Each technique has its certain applications, staminas, and limitations, and commonly a combination of approaches is employed to accomplish detailed evaluation results. Proficiency of these methods boosts the reliability and resilience of bonded structures, lining up with security and efficiency expectations.

Identifying Common Problems

Porosity, defined by gas pockets within the weld, reduces the weld's toughness and resilience. It usually arises from contaminants or inappropriate securing gas. Splits, which can take place during or after welding, position significant risks as a result of their possible to circulate under stress. They commonly emerge from extreme stress and anxiety, quick cooling, or incorrect weld layout.

Incomplete fusion, where the weld steel stops working to bond totally with the base product, weakens the architectural honesty, causing weak joints. This problem normally comes from inadequate warm input or inappropriate welding technique. Slag inclusions take place when non-metallic products are trapped in the weld, endangering its toughness and top quality. These are commonly an outcome of inadequate cleaning between weld passes or improper flux usage.

Determining these issues with meticulous inspection techniques, such as aesthetic exam, ultrasonic screening, or radiography, is critical. Addressing these worries guarantees weld quality, inevitably supporting the structural integrity and safety visit the website and security of the constructed setting.

Enhancing Structural Efficiency

Recognizing the importance of recognizing typical weld issues naturally causes exploring techniques for improving structural performance. The foundational technique for boosting efficiency involves employing advanced welding techniques and products that reduce issue event. Utilizing high-quality filler materials and making sure correct warmth control can considerably minimize concerns such as porosity and cracking, thereby enhancing the weld's visit this website integrity.

Including cutting edge welding innovations, such as laser welding and rubbing mix welding, more enhances architectural strength. These strategies supply exceptional accuracy and minimized thermal distortion, directly impacting the longevity and strength of the bonded structures. In addition, adopting automated welding systems can make sure regular and repeatable weld quality, reducing human mistake.

Additionally, applying extensive pre-weld and post-weld procedures is important. Appropriate joint style, surface area prep work, and stress-relieving procedures add to optimal weld performance. Performing extensive pre-weld assessments enables very early detection of potential problems, helping with timely improvements before they endanger the framework.

Long-term Benefits of Inspection

Through watchful evaluation methods, the lasting advantages to architectural stability ended up being progressively apparent. Constant and detailed welding inspections play a vital function in preventing structural failings by determining disparities and problems early in the building procedure.

Furthermore, normal evaluations add to keeping conformity with market criteria and policies, therefore preventing lawful and financial effects. This adherence to quality assurance not just improves the reliability of the framework yet also fosters trust among stakeholders, including clients, designers, and regulatory bodies. The thorough paperwork of examination end results works as a valuable source for future repair and maintenance efforts, helping with educated decision-making.

Additionally, effective inspection techniques support technology by integrating sophisticated technologies such as non-destructive testing and electronic imaging, which can enhance accuracy and effectiveness. This technological integration additionally highlights the dedication to quality in architectural stability. Inevitably, purchasing thorough welding inspections is a sensible strategy that yields considerable lasting advantages, guarding both the economic and physical financial investment in infrastructure tasks.

Final Thought

Effective welding assessment plays an essential function in enhancing architectural honesty and durability by recognizing flaws early in the construction procedure. Utilizing strategies such as aesthetic inspection, ultrasonic testing, and radiographic testing ensures the detection click this site of concerns like fractures and porosity that jeopardize weld toughness. Extensive evaluations ensure compliance with market requirements, therefore prolonging the life-span of frameworks, lessening pricey repairs, and promoting stakeholder depend on in the integrity and safety and security of welded buildings.

In the realm of construction and design, the importance of welding assessment can not be overemphasized, as it plays a critical role in making certain structural integrity and prolonging the life expectancy of tasks.Ensuring the architectural stability and safety and security of bonded constructions mandates rigorous welding inspection procedures.Structure upon the importance of welding evaluation in securing structural stability, understanding the essential assessment techniques becomes imperative for effective implementation. Effective welding evaluation includes an array of techniques created to evaluate weld high quality, ensuring compliance with rigid design requirements - Welding Inspection Madison.Effective welding evaluation plays a vital role in enhancing structural honesty and long life by determining issues early in the construction process

Report this page